Keeping Up With The Industry, Along With The Nature

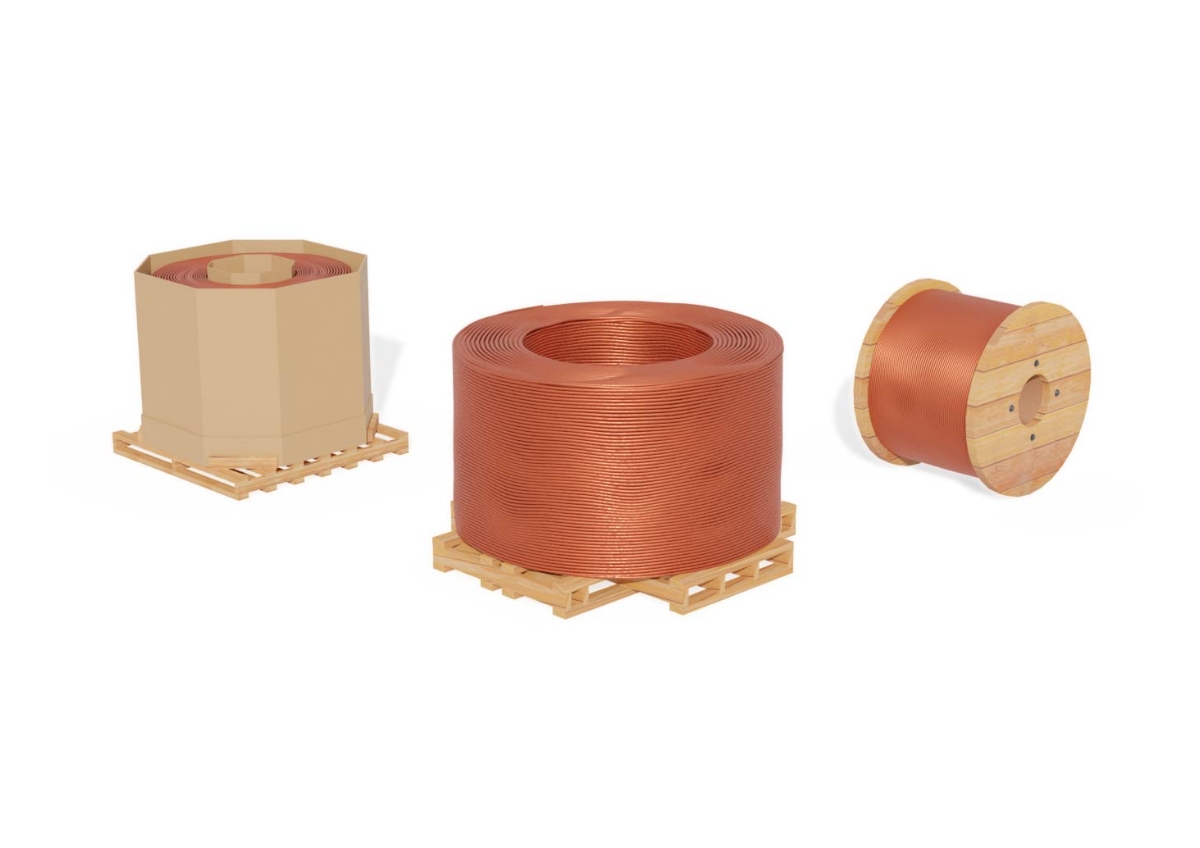

Purification of combustion gases, by process reduction, cooling the gases and splitting harmful particles.

Purification of combustion gases, by process reduction, cooling the gases and splitting harmful particles.

Purification of combustion gases, by process reduction, cooling the gases and splitting harmful particles.